Reduction of ergot alkaloids in wheat

- Customer : BIOWANZE

Date of completion :

July 2022

At the request of BIOWANZE, we recently carried out a project aimed at eliminating ergot alkaloids from wheat during the cleaning phase before milling.

Structural adaptations and floor adjustments have been made in the building, in order to facilitate cleaning and optimize the process in the factory.

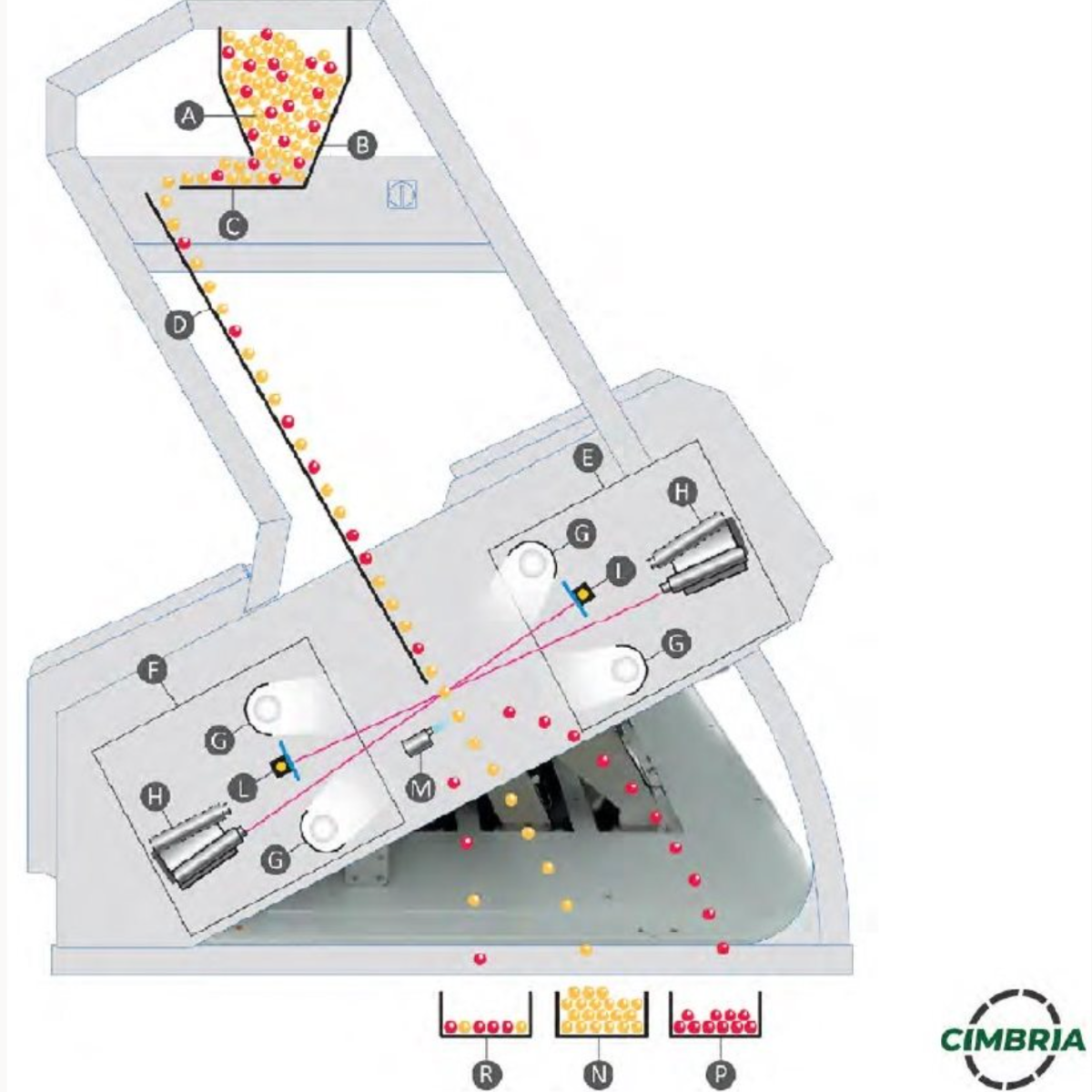

Existing handling circuits have been modified to incorporate optical sorting machines to effectively remove ergot from wheat.

New handling equipment has been incorporated, such as chain conveyors, screw conveyors and belt elevators to facilitate the movement of wheat during cleaning.

In addition, for reasons of efficiency, the compressed air network has been specially adapted.

Finally, particular attention was paid to dust removal from process and handling equipment, with the installation of specific dust removal circuits.

Throughout this project, our team ensured compliance with ATEX standards.

Share this project !

Most recent projects

Installation of a new reverse osmosis system

Installation of a new reverse osmosis system Customer : BENEO ORAFTI Date of completion: June 2023The company BENEO ORAFTI called on our services for the installation of a fourth reverse osmosis system on their Oreye site. This project began with detailed on-site...

New vertical diffusion

New vertical diffusion Customer : Raffinerie Tirlemontoise Date of completion: June 2023We were approached by the company Raffinerie Tirlemontoise to replace two horizontal diffusions with a vertical diffusion. Our support began with monitoring the civil engineering...

Addition of a sand filter

Addition of a sand filter Customer: BIOWANZE Date of completion : July 2020Known for its exploitation of new energy sources from renewable energies, the company BIOWANZE called on our expertise for the extension of its water treatment unit in the wastewater treatment...