Revamping a cement kiln cooler

- Customer : CCB Cementir Holding

Date of completion :

January 2021

CCB Cementir Holding, a company specializing in the production of aggregates and ready-mix concrete, called on our expertise. This project involved revamping the cooler on kiln 4 of their cement plant, which has a production capacity of 4,500 tonnes per day.

Our intervention began with an in-depth study to assess the feasibility of modifications to the cooler, aimed at improving its performance in line with the indications provided by the customer.

Precise calculations and detailed drawings were carried out, to design new mobile frames for the cooler inlet grate. Customer-specific data were taken into account, such as operating temperature, as well as static and dynamic loads.

In addition, we carried out calculations and created detailed drawings for the new mobile frame support shafts, using static beams with a width of over 5 meters. These elements were essential to ensure the stability and durability of the mobile chassis.

As part of the project, we also drew up detailed plans for the bearings supporting the rollers on the moving grilles. These plans took into account the customer’s specific requirements, in particular the use of smooth rollers and guide rollers with flanges, incorporating specific bearings.

To ensure optimum sealing, detailed plans were drawn up for the bulkhead seals at the passage of the mobile frames, to avoid any undesirable leaks.

Finally, our engineers were present on site, accompanying the customer throughout the entire process, to ensure close monitoring and periodic control of the work.

Share this project !

The most recent projects

Addition of a sand filter

Addition of a sand filter Customer: BIOWANZE Date of completion : July 2020Known for its exploitation of new energy sources from renewable energies, the company BIOWANZE called on our expertise for the extension of its water treatment unit in the wastewater treatment...

Construction of a storage tank

Construction of a storage tank Customer: BIOWANZE Date of completion: April 2023Our company was selected by BIOWANZE for the engineering of a 3,000 m³ tank for the storage of Protiwanze, a protein-rich animal feed. The foundations of the new reservoir were carefully...

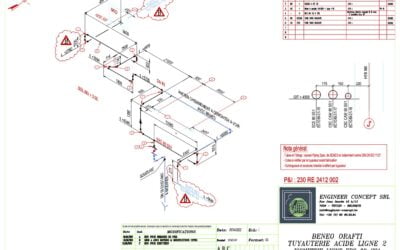

Replacement of sulfuric acid pipes

Remplacement de tuyauteries d’acide sulfurique Client : BENEO ORAFTI Date de réalisation : 2022 et 2023La société BENEO ORAFTI a fait appel à nos services pour un projet de remplacement de tuyauteries d'acide sulfurique. Les travaux consistent à remplacer environ 575...